Balancing Stability and Installation Efficiency in Large-Scale Aluminum Truss Structure

The customer from Thailand planned to build a large-scale aluminum truss system with a size of 20 × 20 × 15 m. The project was not only large in volume and high in structure, but also put forward strict requirements for overall stability, safety redundancy and engineering reliability.

The customer clearly pointed out that it was inconvenient for traditional spigot trusses to be installed in large structures. During the installation process, a large number of high-altitude holes and pin operations were required, which not only resulted in low construction efficiency, but also relied on the experience of on-site personnel, thereby increasing the difficulty and potential risks of construction. Therefore, the customer hoped that GF-Truss can provide a set of customized truss solutions that would ensure the safety and reliability of the structure and significantly improve the efficiency of on-site installation.

Project Requirements and Limitations of Conventional Spigot Truss Systems

During design, GF-Truss did not simply follow the traditional scheme, but conducted an in-depth evaluation of the application of traditional spigot trusses in large structures from the actual installation conditions. The spigot connection was relatively limited in the multi-section truss splicing and high column structure.

Based on these problems, we proposed adopting the male and female connector structure as the core connection method. The structure was inserted into the tube end, allowing adjacent truss sections form a continuous force path at the joint, improving the overall force uniformity and connection rigidity. At the same time, the male and female connectors have good automatic alignment characteristics, which effectively simplified the on-site installation process, which was especially suitable for large-span, high-column and high-safety truss application scenarios.

Structural Configuration and Material Optimization for Large-Scale Truss System

Combined with the overall size of the project 20 × 20 × 15 m and the use scenario, the structure was defined as a large-scale, high column and multi-node connection engineering project. Compared with conventional trusses, this cross-sectional size offered clear advantages in bending resistance and overall torsional rigidity. It also effectively controlled the overall deformation and lateral displacement of the 15m-high structure under load.

Customized Design and Production Guarantee

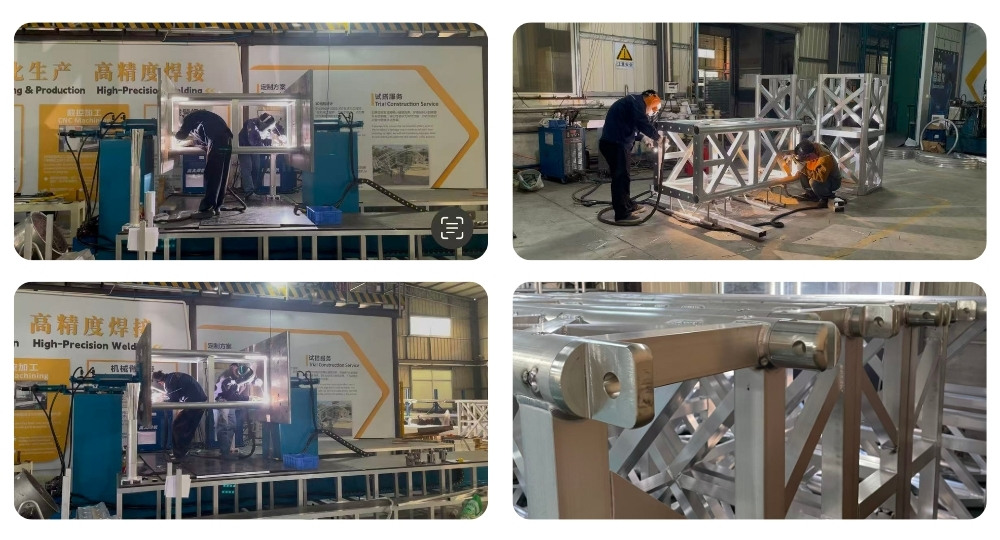

For the non-standard large-section truss specification of 550 × 1500 mm, GF-Truss specially invested in customized welding molds that match this specification and the structure of male and female joints during production.

While welding, GF-Truss strictly controlled the welding angle, node position, and overall geometric accuracy. This ensured each truss remained highly consistent in terms of cross-section morphology, node position, and connection accuracy. The standardized production not only reduced the uncertainty caused by human error, but also enabled the male and female joints to achieve a smoother plug-in effect when installed on site, and avoided forced adjustment or secondary processing caused by dimensional deviation.

Multi-Span Load Test and Safety Evaluation

After production, GF-Truss conducted a rigourous TÜV SÜD voluntary load-bearing test on the 550 × 1500 mm large-section truss system. The test covered a variety of spans of 40 m, 30 m, 20 m and 10 m, and combined a variety of load-bearing conditions to comprehensively verify the bearing capacity and deformation control of the structure.

Based on the multi-span and multi-condition test results, the system demonstrated sufficient safety margin in terms of safety, stability and engineering reliability.

Aluminum Truss Test Assembly and On-Site Installation Validation

After completing the load-bearing test, GF-Truss conducted a partial structural test verification for the customer. The test included a rectangular structural unit and a set of 800 × 800 mm aluminum truss lifting system.

During the trial assembly process, the male and female connector joints were assembled smoothly, which effectively reduced the on-site adjustment time. Through actual assembly, the customer was able to clearly understand the installation sequence and on-site operation process, so as to build intuitive confidence in the feasibility and safety of the overall truss structure.

Flexible and Reliable Delivery Support

Two days before the project was about to be shipped, the customer temporarily proposed to spray the whole structure in black to meet the visual needs of the final use scenario. In the face of time-tight adjustment needs, GF-Truss quickly evaluated the process and schedule, under the premise of not affecting the overall delivery timeline. The delivery plan was coordinated and adjusted, and the spraying process was successfully completed.

Container Loading and Project Delivery

On December 18, 2025, GF-Truss completed the loading of two containers in one day as scheduled according to the customer's project plan.

Considering that the structure of this project was large and heavy, and included different specifications of main trusses, column units, base components and connecting accessories. Before loading, GF-Truss carried out a systematic zoning and loading plan for the overall structure. According to the truss length and cross-section dimensions, loading sequences and placement were arranged to improve container space utilization and avoid deformation risks during transportation.

From Engineering Design to Real-World Execution

In large-scale structural projects, the real challenge often lies not in the design itself, but in how to make the truss system safely and smoothly built and used on site. Through standardized structural logic, customized node design and strict testing process, we strive to ensure that each set of truss system still has stable structural performance and predictable installation performance under different truss project conditions.

Leave A Message

Scan to Whatsapp :

Hi! Click one of our members below to chat on