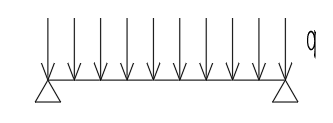

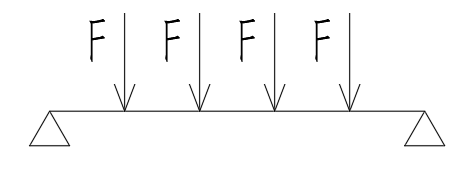

This week, GF-Truss invited TÜV SÜD, a globally authoritative certification body, to conduct a professional load-bearing test on our 550mm×1500mm heavy-duty aluminum truss, covering four spans: 10m, 20m, 30m and 40m. To ensure data accuracy, professional technicians completed preliminary mechanical simulation calculations based on the truss specifications and structure before the on-site load test. During the official test, the technical team accurately marked the truss loading points, adopted the method of uniformly applying the target load at one time, recorded the truss deflection after one hour of standing, and strictly followed TÜV SÜD test standards throughout the process.

Test Procedure and Methodology

The on-site load-bearing test was conducted under a clearly defined and controlled procedure:

All test operations were witnessed and evaluated by TÜV SÜD experts to ensure consistency with applicable certification requirements.

Field Test Proves Strength: Impressive Full-span Load Data Exceeds Expectations

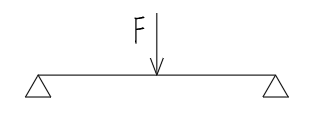

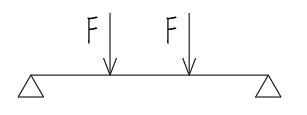

Online mechanical simulation showed that the ideal uniform load capacity of the 40m-span truss is 6500KG. In the on-site test, the technical team evenly distributed 9750KG across 10 loading points, with the truss deflection only reaching 270mm, well within the safety threshold. Further targeted tests yielded more convincing data: for the 40m-span truss, deflection was 110mm under 2000KG central load and also 110mm under 6000KG four-point load.

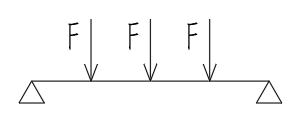

Drawing on the mature experience from the 40m test, the 30m-span truss test proceeded efficiently. With 12000KG evenly distributed across 12 loading points, deflection was 130mm; it measured 67mm under 4000KG central load and 97mm under 8000KG four-point load, all meeting safety standards. The full-span test results fully demonstrate the excellent load-bearing capacity and structural stability of the trusses.

| Load Table | |||||||||||

| 550*1500mm Aluminum Beam Truss | 4-side Brace Tube | Aluminum Alloy 6082-T6 |

Main tube: ø100x8mm |

Vice tube: 80x80x5mm |

Brace tube: 60x60x4mm |

Test Date: 14 Dec 2025 |

|||||

| Span | Initial Value | Unif. distributed load | Center point load | Third point load | Quarter point load | Fifth point load | |||||

|

|

|

|

|

|||||||

| Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

||

| m | mm | kg | mm | kg | mm | kg | mm | kg | mm | kg | mm |

| 40 | 1340 | 9750 | 270 | 2000 | 110 | / | / | 6000 | 110 | ||

| 30 | 1400 | 12000 | 130 | 4000 | 67 | 7000 | 95 | 7500 | 97 | 8000 | 97 |

| 20 | 1400 | / | 5000 | 26 | 6000 | 29 | / | / | |||

| 10 | 1400 | / | 5000 | 5 | / | / | / | ||||

Test Empowers Truss Quality

The successful TÜV load test confirms the strength and reliability of our truss and reflects the dedication and expertise of GF-Truss. From careful simulation to meticulous on-site testing, every step was taken to ensure accuracy and safety. These results can give our customers confidence in the performance of our products and demonstrate our commitment to engineering solutions that meet the highest standards. Each test is not just a measure of strength, but a step toward delivering reliable and trusted structures for real-world applications.

Leave A Message

Scan to Whatsapp :

Hi! Click one of our members below to chat on