This 550*1500mm truss is designed by GF-Truss for large events that require extreme loads. Under the span of 40 m, its maximum carrying capacity can reach 6,500 kg, which can meet the needs of high-intensity, large-scale stage and performance aluminum truss structures. It is made of high-strength aluminum alloy 6082-T6. The main tube uses ø100×8 mm round tube, and the vice tube and brace tube all use 80×80×5 mm square tube, which effectively improves the overall rigidity and stability.

Item No :

V5515Connection :

Pins, R-clipsProduct Origin :

Guangzhou, ChinaColor :

Sliver/BlackSurface Finish :

SprayingAvailable Length :

2000/2500/3000/3500/4000/4500/5000mmProduct Introduction

High-loading Heavy Truss Aluminum Spigot Truss 550×1500mm

The 550*1500mm aluminum truss is equipped with a smart male and female connection system (pin-fork type), which significantly reduces the difficulty of installation and improves the efficiency and safety of on-site installation. In practical applications, this 550*1500mm truss is ideal for concerts, music festivals, sports events and large-scale outdoor activities and other scenes with high requirements for span and carrying capacity. It is especially suitable for the main stage structure that requires centralized hanging lighting, audio and LED screen display systems. It can still maintain good stability under high concentrated load and complex working conditions.

Product Parameters

|

Material |

Aluminum Alloy 6061-T6/6082-T6 |

|

Size |

550×1500mm (4-side Brace Tube) |

|

Color |

Silver/Black |

|

Main Tube |

⌀100*8.0mm |

|

Vice Tube |

80*80*5.0mm |

|

Brace Tube |

80*80*5.0mm |

|

Available Length |

2000/2500/3000/3500/4000/4500/5000mm |

Product Advantages

Structural Capacity for Extreme Load and Super-span

The 550 x 1500mm aluminum truss is specially developed for super-span and extreme load conditions. Under the span of 40 m, its overall carrying capacity can reach 6,500 kg, which can meet the needs of the centralized arrangement of lighting, sound and LED display systems on large stages. The structural design takes practical engineering applications as the starting point, emphasizing safety redundancy and long-term stability, so that it can meet the high requirements for the main load-bearing structure in large-scale activities.

Structural Design Optimized for Long-span Conditions

Our 550 x 1500mm truss is engineered to take the stress off your mind. We've arranged the round main tubes to handle the heavy lifting, while the square support tubes lock in stability and prevent twisting. This smart division of labor means less sagging and rock-solid performance, giving you a safe, reliable backbone for your biggest setups.

Enhancing On-Site Efficiency with Aluminum Alloy 6082-T6

Using aluminum alloy 6082-T6 allows us to offer the best of both worlds: incredible strength and manageable weight. Unlike heavy steel alternatives, this truss is easier to ship and much faster for your crew to handle on-site. Whether you are setting up or tearing down, the reduced weight lowers physical strain and speeds up the process, making it the ideal choice for touring productions or large-scale events with tight schedules.

Smart Male and Female Connectors

Large-sized aluminum trusses are difficult to align during the installation process. This truss adopts an intelligent male and female connectors (pin-fork type), which makes it easier for components to achieve rapid docking during assembling. This connection effectively reduces the difficulty and time of high-altitude manual adjustment, reduces installation errors and construction risks. It greatly improves the overall installation efficiency and on-site safety.

| 500*1500mm Aluminum Beam Truss | 4-side Brace Tube | Aluminum Alloy 6082-T6 |

Main tube: ø100x8mm |

Vice tube: 80x80x5mm |

Brace tube: 60x60x4mm |

Test Date: 14 Dec 2025 |

|||||

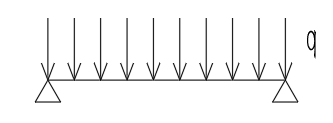

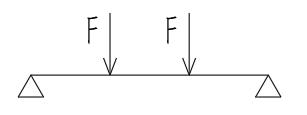

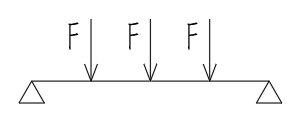

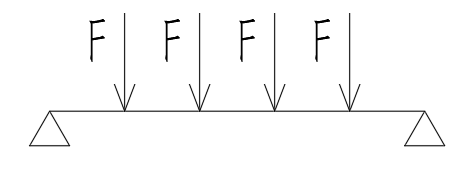

| Span | Initial Value | Unif. distributed load | Center point load | Third point load | Quarter point load | Fifth point load | |||||

|

|

|

|

||||||||

| Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

Full load | Central deflection |

||

| m | mm | kg | mm | kg | mm | kg | mm | kg | mm | kg | mm |

| 40 | 1340 | 9750 | 270 | 2000 | 110 | / | / | 6000 | 110 | ||

| 30 | 1400 | 12000 | 130 | 4000 | 67 | 7000 | 95 | 7500 | 97 | 8000 | 97 |

| 20 | 1400 | / | 5000 | 26 | 6000 | 29 | / | / | |||

| 10 | 1400 | / | 5000 | 5 | / | / | / | ||||

Application

|

|

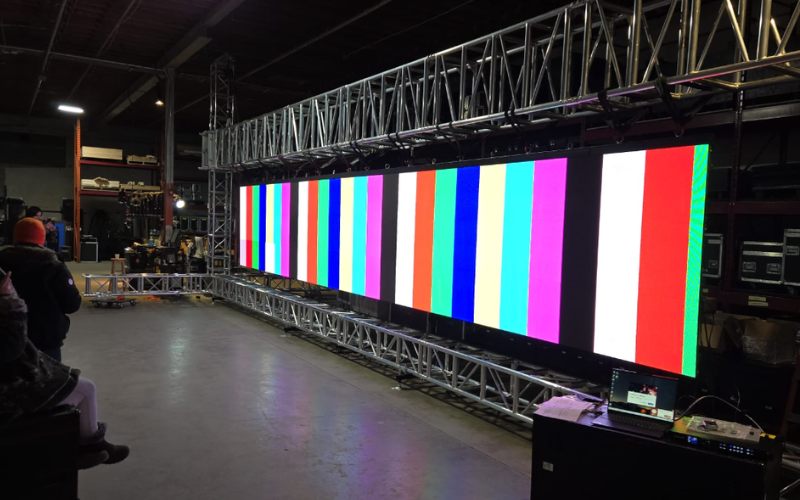

| Large-Scale Concert Stage Structure | LED Wall Support |

|

|

| Live Show Event & Stage Structure System | Temporary Outdoor Event |

TÜV SÜD Load Testing

Under the witness of TUV SUD, GF-Truss had conducted a systematic load-bearing test on the 550×1500mm aluminum alloy truss. The test span covered 40m, 30m, 20m and 10m, and simulated common working conditions such as uniform load, centre point load and multi-point concentrated load respectively.

The test results show:

Through repeated verification of different spans and loading methods, we can more clearly grasp the load performance of this model truss in actual engineering, and provide a reliable and referenceable safety basis for large-scale activities and complex application scenarios.

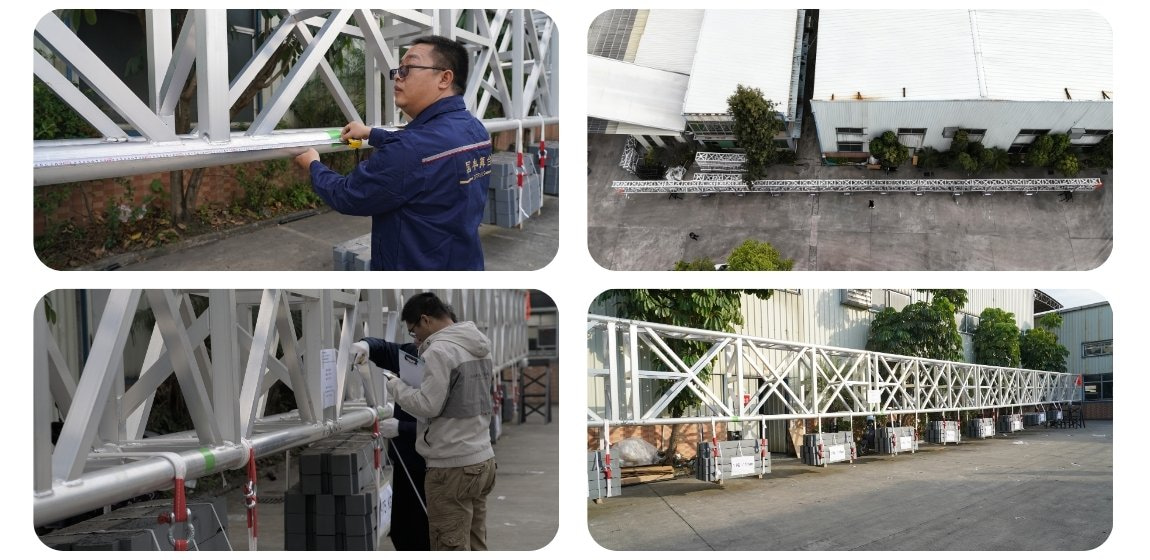

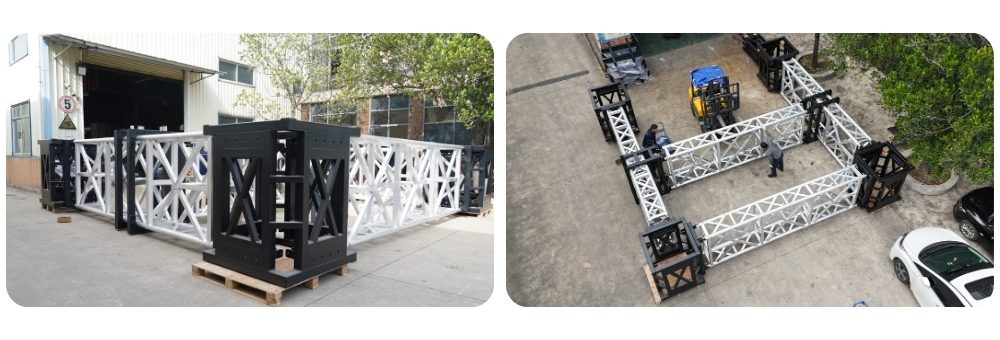

On-Site Trial Assembly

This test is mainly used to show the 550×1500mm truss in the actual project, helping customers to understand its carrying capacity and installation order more intuitively. Whether it is used for stage construction, LED display support, or large-scale activity structure applications, this 550*1500mm aluminum fork truss can provide stable and reliable structural support and provide a clear reference basis for subsequent project implementation.

Leave A Message

Scan to Whatsapp :

Hi! Click one of our members below to chat on